|

This is a handy compact machine capable

of handling cabinet work, light door work, sash stuff, etc, at high rates

of production, it has been specially designed for fast, easy operation.

Adjustments are readily accessible and easy to make. It is completely

modern in design and is both economical in first cost and in maintenance. |

|

The machine will tenon, scribe the

shoulders and cut off to length at one pass of the table. It will take

timber 300mm wide x 115mm deep and cut tenons upto 5” long at one pass. |

| |

|

CONSTRUCTION: |

|

HORIZONTAL

HEADSTOCKS |

|

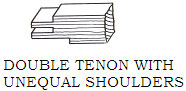

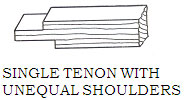

These are each arranged with an

electric motor built in. The Spindles are made from special steel of 40

tons tensile strength and mounted in heavy ball bearings. Both headstocks

are adjustable vertically. Horizontal adjustment is also provided to both

top and bottom spindles for producing tenons with unequal shoulders.

|

|

Provisions are also made for adjusting

both heads together so that the operator may position the tenon when once

set for thickness. |

|

The Cutter Blocks are designed to give

a shearing cut. Special cutters are fitted for giving a clean and accurate

finish to the shoulders of the work. The cutterblocks are secured to the

spindles by keys and locknuts. |

| |

|

VERTICAL SCRIBING OR COPE SPINDLES: |

|

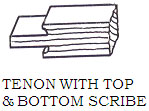

The Vertical Scribing spindles are each

attached to the Main Headstock slides and are, adjustable with them. In

addition, they have independent Vertical and Horizontal adjustments, all

of which may be operated while the machine is running. A Separate motor is

built into each head. The scribing cutter blocks are of steel and have

four dovetail slots for carrying the slotted scribing cutters. The cutter

blocks are secured to the spindles by keys and locknuts. |

|

Spindles are arranged to take 275 mm

diameter grooving saws. |

|

|

|

|

| |

|

CUTTING-OFF SAW |

|

The cutting-off saw is fitted at the

back of the Cutter Blocks and is. Therefore, well out of the way of the

operator. The Saw Spindle is mounted in ball bearings and carries a 300mm

diameter saw. It is mounted below the table and is horizontally adjustable

by Screw and Hand wheel to suit the length of the tenon. A guard is

provided over the saw. |

| |

|

MOTORS |

|

The motors are built into the

headstocks and are dust tight, thus making impossible the entrance of dust

or chips, which reduces maintenance to a minimum. They are made up of

motor and stator units and built directly into the machine with the cutter

heads mounted on the extended motor shafts and can be supplied to operate

from two or three-phase alternating current of any voltage. The shafts

revolve in heavy type ball bearings enclosed in dustproof housings. |

| |

|

CONTROL GEAR |

|

The motors are controlled from a

centralized push-button station, and the control gear is of the automatic

contactor type. The contactor gear is built into the main frame and is

dust-tight. A master stop shuts down all motors simultaneously and

embodies a “lock-nuts” feature which make it impossible fo the machine to

be started inadvertently. |

| |

|

TABLE

|

|

The table is, mounted on ball bearing

rollers. The runways are accurately machined, and scrapers are fitted to

keep them clean. The table is so arranged that perfect alignment with the

cutter blocks is always maintained. |

| |

|

TABLE FENCE |

|

The table fence is provided with a

turnover stop which can be utilized with equal facility whether the fence

is in the square or angular position. In addition a spring stop running

the full width of the table is provided to enable the table to be loaded

with narrow stock, such as sash bars. A quick-acting lever clamp is fitted

for securing the work. (Pneumatic Clamping can also be provided at extra

cost). |

| |

|

A dead stop is also provided for use in

conjunction with the shoulder stop on the fence. This is adjustable along

a bar and can be locked where desired. |

|

|

|

|

| |

|

SPECIAL FEATURES

|

|

1. The machine is compact and

economical in floor space. |

|

2. The machine can be fitted with

Tenoning and Scribing heads and cut-off saw. |

|

3. All heads are direct motorized. All

motors are totally enclosed and of ample power for the heaviest work. |

|

4. Tenon and scribing heads have

combined and independent vertical adjustment. |

|

5. Smooth, easy table movement on ball

bearing rollers, ensures fast operation and high rated output. |

6. Table carries swiveling fence with

turnover stop. Spring stop is

provided across table for loading narrow stuff. |

|

7. Quick-acting duplex single lever

clamp. (Pneumatic Clamping Optional) |

|

8. Scribing spindles are arranged to

take 275mm diameter-grooving saws. |

| |

|

Some of the many

operations that can be done on the Single End Tenonner :: |

|

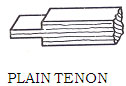

1. Plain Tenon |

|

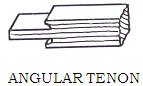

2. Angular Tenon |

|

3. E-halving joint |

|

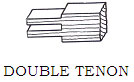

4. Double Tenon |

|

5. Double Tenon with unequal shoulders |

|

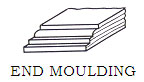

6. End Moulding |

|

7. Single Tenon with unequal Shoulders |

|

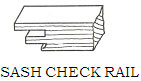

8. Sash Check Rail |

|

9. Tenon with Top & Bottom Scribe |

|

|

|

|

| |

|

|

|

PRINCIPAL DIMENSIONS

AND CAPACITIES: |

| - Will admit timber

upto |

: |

355mm x 115mm |

| - Will cut tenons at

one operation |

: |

127mm long |

| - Fence may be swiveled

45° for angular tenons |

|

|

| - Top cutter head will

rise 1085mm above table |

|

|

| - Will take 1525mm

between shoulders of Tenons using turnover stop |

|

|

| - Size of table

|

: |

760mm x 405mm |

| - Height of table from

floor |

: |

840mm |

| - Diameter of

cutting-off saw |

: |

305mm |

| - Diameter of

horizontal and scribing Spindles |

: |

31.7mm |

| - Speed of all motors,

RPM |

: |

3000 (Approx.) |

| - Horse Power of motors

for horizontal cutter heads |

: |

2 x 5 H.P |

| - Horse Power of motors

for scribing heads |

: |

2 x 2 H.P |

| - Horse Power of Motor

for rear cut-off saw |

: |

1.5 H.P |

| - Total Connected Load

of this machine |

: |

15.5 H.P |

| - Floor space approx.

|

: |

1525mm x 1450mm |

| - Net weight approx.

Complete Machine With cut-off saw |

: |

1040 Kgs. |

| - Gross Weight approx.

complete machine with cut-off-saw |

: |

1220 KGS |

| - Shipping Dimensions

|

: |

3.5 c.m. |

| |

|

|