|

|

OAV EDGEBANDING MACHINE – MAX360A |

|

|

|

OAV's TAIWAN Edgebander MAX360A is

industrial grade heavy duty machine with CORNER ROUNDING function which

brings you the perfect high-quality result on the workpiece. Coils up to 3mm

thick, and strip up to 4mm thick, the machine is equipped with a 1.2KG

capacity Teflon coated glue tank, auto gluing, edge cutting, end trimming,

flush trimming, scraping, and buffing functions.

A user-friendly adjustment’s with numerical indicators as well as TOUCH

SCREEN display for all operation, PLC parameter setting’s, temperature

control, allows for stable and reliable working conditions. |

|

|

| |

Unparallel with unique functions including PLC I/O

diagnostics, parameter editing & checking directly

connection with the PLC programe and adjustments. |

| |

It

support 128MB Flash + 128MB DDR3 for storage of job

programs and screen data. |

| |

Users

are able to access all information and adjustment in 7

multi language including English, Spanish, Russian,

Hungary, Czech and Polish. |

| |

Old

record’s for service and future reference for maintenance. |

| |

In-program alarm notification brings you the most

efficient trouble shooting process on this comprehensive

machine. |

| |

Auto

Troublepass function prevents the damage from accident

panel feeding or malfunctioning. |

|

|

|

|

|

|

|

|

AUTOMATIC PRESSURE BEAM

The height of the pressure beam can adjusted automatically

according to the thickness of the panel being process. Rapidly

increase the operating efficiency for the end users. |

|

|

|

|

HEAVY DUTY CHAIN FEEDER

The steady work piece feeding mechanism has a chain and

set of driving rollers, which will leave no scratches on the

work-piece surface.

|

|

|

|

|

|

PREHEATING UNIT

Preheating units provides 0.4KW heating power to apply heating

on the humid panel side before edge banding.

|

|

|

|

|

|

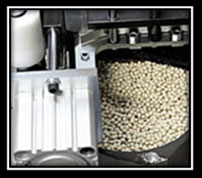

GLUE

POT UNIT

The 1.2kgs Teflon-coated glue pot is designed for EVA

hot-melt glue as well as PUR Glue. This option has to be

ordered in advance and cannot be added later. (This is a

optional attachment at extra cost) The glue is applied with an

adjustable glue roller on the job.

|

|

|

|

|

|

THE CORNER ROUNDING UNIT

The compact corner rounding unit brings the ability of

trimming to the very highest level. All the essential

functions of trimming are programmed by the operator and

executed at high speed to an exceptional degree of accuracy,

providing the finest basis for efficient operation, leading to

higher productivity.

Auto trouble pass feature is applied to this unit especially

to prevent the manufacturing on other units or too fast panel

feeding

|

|

|

|

|

|

END CUTTING UNIT

This unit is mounted on high-precision linear bearing.

Which ensure perfect cutting results. The high frequency

motors with 12,000 rpm gives a clean cut.

|

|

|

|

|

RADIUS SCRAPING UNIT

Accomplishing a very good finish by smoothing trimmed

edges with this unit.

FLAT SCRAPING UNIT (OPTIONAL) Accomplishing an most favorable

appearance by removing the leaked or left glues remained on

the edge

|

|

|

|

|

EDGE SCRAP CHIP

COLLECTION BOX

Guarantee’s the chip free for better finished.

|

|

|

|

|

BUFFING UNIT

The buffing unit leaves a super finish on ABS and PVC

edging, and removes any discoloration on the edges, which is

especially noticeable when working with dark edge material.

|

|

|

|

|

|

MODEL |

MAX360A EVA/ PUR |

|

Feeding Speed |

11 M/Min. |

|

Panel Thickness |

8-45 mm |

|

Edge Thickness |

0.4-3 mm |

|

Mini. Panel width |

90mm |

|

Mini panel length |

220mm |

|

Working table height |

940mm |

|

Extensible support width |

560mm |

|

Extraction connector |

Ø 125 mm X 2 |

|

Total Motor Power |

5.9 kw |

|

Overall Size |

3700*1003*197mm |

|

Weight, kg (N.W./G.W.) |

830/950KG |

|

Packing size |

3550*720*1660mm |

|

UP/down |

12,000 r.p.m. |

|

Front/rear |

12,000 r.p.m. |

|

Corner rounding unit |

12,000 r.p.m. |

|

Buffing Speed |

3000rpm |

|

Power (kW) of each motor |

|

|

Feeding motor |

0.75 (Kw) |

|

Glue spindle motor |

0.24 (Kw) |

|

Front/rear trimming motor |

0.22 (Kw) |

|

upper trimming motor |

0.37 kw |

|

lower trimming motor |

0.37kw |

|

upper buffing motor |

3ph -0.12kw, 1ph -0.18kw |

|

lower buffing motor |

3ph -0.12kw, 1ph -0.18kw |

|

pre-heating |

0.4kw |

|

corner rounding motor |

0.37kw\ |

|

glue pot (5 elements) |

1.315kw |

|

Weight |

720kg |

|

|