|

ELECTRICAL CONTROL

SYSTEM |

|

| New

Electronic Control board with Touch Screen & PLC |

|

| Besides having completely

changed the general switch board control design, the location of the

control switches have been conceived completing them with clear and simple

visual references. |

|

| |

|

|

The traditional instruments have been

replaced by DIGITAL TOUCH SCREEN assuring, Easy Control and high precision

and longer durability. |

| |

|

The PLC has the function of controlling

the Pressing Cycle, temperature and the Pressure. It can store upto 21+1

Working Cycles ( More on request) which can be recalled for different

products on the Touch Control Panel. This function helps to save a lot of

time while changing From one type of job to another & to remember the

parameters of different types of jobs. |

| |

|

All working cycles parameters are

settable and stores in a memory bank thus making Sandeep Hot Press highly

Flexible and Productive. |

| |

The general switchboard has been placed

on a special door with

a opening, allowing maintenance operation easily performed. |

| |

|

On the digital display the operator can

set and/or adjust all press functions, particularly: |

| |

|

Setting of working Pressure

Setting of working temperature

Setting of the timer to adjust the pressing time.

Setting of automatic switching ON / OFF of the heating unit.

Automatic Switching On / OFF of the Thermo fluid Pump. (Stops only when

temperature falls below 60° C) |

|

| |

|

|

Lockable power general switch to avoid

the use of the press by not authorized people. |

|

|

The Machine can not be used with out

password. |

|

|

Safety device by means of a sensor.

This accessory avoids, by blocking the press movement, damages to the

platen structure, in case an incorrect loading operation should take place

with panels of different thickness. |

|

|

Two Perimetral safety cable with tear

switch. |

|

|

In case of operating of Control Panel,

the supply is automatically disconnected. |

|

|

Pressure Transtrader of Kobold (German)

Brand for accurate pressure display. |

|

| |

|

|

TECHNICAL SPECIFICATIONS: |

|

|

| * Platen Sizes

|

: |

2500mm × 1300mm |

| * Maximum Pressure of

Platen/Total Thrust |

: |

100t (3.1 Kg/cm2) |

| * Maximum Temperature

of Platen’s |

: |

120˚C |

| * Maximum Opening of

the Platen/Stroke / Day Light |

: |

300mm |

| * Hydraulic Cylinder’s

|

: |

100mm Diameter |

| * No. of Cylinders

|

: |

6 Nos. |

| * Hydraulic Pump Power

(Imported) |

: |

5.5 KW |

| * Hot Oil Pump Power

(Imported) |

: |

2.2 KW |

| * Weight |

: |

6200KG (Approx) |

| * Dimensions of the

Machine |

: |

3300 × 1650 × 2050mm |

| * Voltage |

: |

415 Volts , 3 Phase, 50

Hz |

| |

|

|

|

Minimum Overall dimensions, operating Easiness and safety. |

|

Characteristics, Technical data and

Weights referred to standard machines are not binding. |

| |

|

|

| |

| |

| |

|

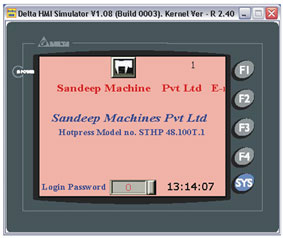

FUNCTIONING OF SANDEEP PROGRAMMABLE HOT PRESS |

| |

|

|

|

On Switching on the

machine, you have to enter the password this feature is incorporated to

avoid any misuse of the machine by unauthorized person. |

| |

|

|

|

Touch the Login

Password Function. The numeric pad will be displayed on the Screen. Feed

the password & press enter. |

| |

|

|

|

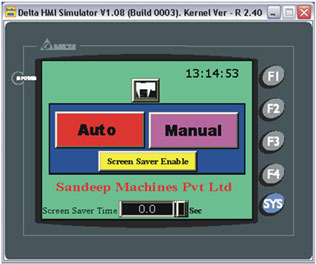

After successfully

entering the password. You can choose how you want to work on the machine.

Either in the Auto mode or the Manual mode. |

| |

|

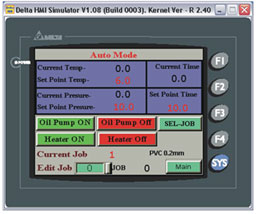

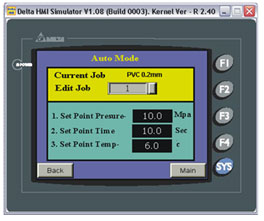

AUTO SETTING – TO START OIL PUMP & HEATER |

| |

|

|

|

The machine has 20 different titled

chapters, in the memory bank. You can alter the parameters i.e. Time,

Pressure or temperature. Parameters of any of the titled chapters. Also

all the titles have mode no from 1 –20. you can recalled the desired

setting / programme either by the name or the mode number i.e. 1 – 20. |

| |

|

The last set parameters will be stored

in the memory bank if the machine is restarted. |

| |

|

To change the parameters, numeric

password has to entered on the numeric pad which Shows when you press Edit

Job. (As shown in the photo below). |

| |

|

The Modes / Parameters you have to set

are Temperature, Pressure & Time of pressing. |

| |

|

Touch the screen on the parameters you

want to set .You can feed the valve and press set. |

| |

|

If you go to the Set-Job function. You

go to the preset valves of various types of jobs under their name

headings. |

| |

|

The Display Panel also shows how many

jobs have been completed on this setting.. |

| |

|

AUTO MODE SETTING - EDITING |

| |

|

|

|

When successfully entering the password

you can after the required programme. Press the item (i.e. Pressure, time

or Temperature) the numeric pad shows on the screen (As photo below) you

may feed the required values & press enter. The required values shall be

saved. |

| |

|

Press back to the main Auto mode manual

and operate the machine. |

| |

|

(The machine has a in built counter for

each operation. The Display shall also show the total number of Jobs done.

You may clear the counter if desired. |

| |

|

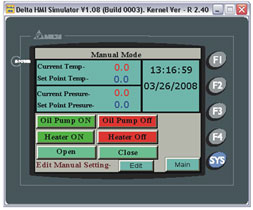

MANNUAL – TO START OIL PUMP & HEATER |

| |

|

|

| If you go

to the Manual Mode. You may set the required parameter of temperature,

Pressure and Time one by one. On touching the required, you get the

display to feed in the values & press set. |

| |

| Also oil

pump & heater may be switched ON/OFF as required. |

| |

| The

machine stores the values of the last set item all the time. |

| |

|

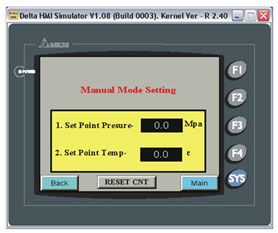

MANNUAL EDITING |

| |

|

|

| You may

feed the required parameters for Pressure, time & temperature one by one. |

| |

| Press each

one of them one by one to get the machine pad (as photo below) and feed

the valve as required. Press enter after putting the new valve. |

| |

| Press back

and go to the manual mode to operate the machine. |

| |

|

For Switching off

the machine. You must switch off the Heater (Keep sure that the oil pump

is working) once the temperature falls bellow 60 C then switch off the

main power switch. Heated thermo fluid oil can cause damage to various

parts of the machine such as the platens, oil seals etc. |

| |

|

AUTO SETTING – JOB SELECTION |

| |

|

|

| This Shows

the various titled jobs done on a Hot Press. You can choose the Mode you

want to work. This will help you to save time and you do not have to set

all the parameters again. This function helps the oeprator for quick

change from one type of work / job to another. |

| |

| Also you

can edit the parameter of any of the Programmes. |

| |

| You may

programe a setting and check it on the Rough work control before feeding

it to the desired title. |

| |

| Any other

addition of the title can be done by one Service Engineer on request. |

| |

|

|

| |

|

|

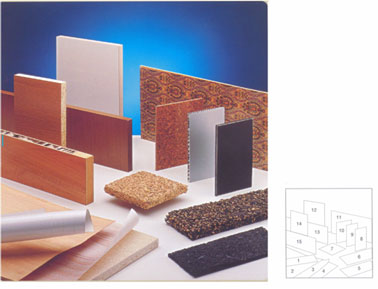

EXAMPLES OF SUITABLE MATERIALS FOR PRODUCTION |

| |

1. High Pressure

Laminate PVC |

| |

2. Veneer |

| |

3. Decorative Paper |

| |

4. Chipboard – MDF |

| |

5. Rubber and Chipboard |

| |

6. Cork and Rubber

Board |

| |

7. Cork Board |

| |

8. Aluminium Composite

Panel |

| |

9. Honeycomb Aluminium

Composite Panel |

| |

10. Cork Panel |

| |

11. Transfer Paper Wood

Panel |

| |

12. Bothside HPL

Covered Board |

| |

13. Veneered Panel |

| |

14. Decorative HPL

Covered Panel |

| |

15. Hollow Care Panel |

| |

|